Description

In the realm of pneumatic tools, Chicago Pneumatic has carved a niche for itself, consistently delivering high-quality products that cater to the needs of professionals across various industries. One such stellar offering from their arsenal is the Chicago Pneumatic CP7900 Reciprocating Air Saw, a tool that exemplifies precision, power, and reliability. In this comprehensive review, we will delve into the technical specifications, unique features, and advantages that make the CP7900 a standout choice in the world of reciprocating air saws.

Technical Information

1. Power and Performance

At the heart of the CP7900 lies a robust pneumatic motor that provides exceptional power and performance. With an air consumption rate of approximately 7 cubic feet per minute (CFM) and an operating pressure of 90 pounds per square inch (psi), this reciprocating air saw is designed to handle a variety of cutting tasks with ease.

The tool’s stroke length, which determines the depth of each cut, is an impressive 3/8 inches. This allows for efficient and precise cutting through a wide range of materials, making the CP7900 a versatile companion in workshops, construction sites, and automotive garages.

2. Speed and Control

The CP7900 features an adjustable speed regulator that allows users to tailor the cutting speed to match the requirements of different materials. The variable speed control ranges from 5,000 to 10,000 strokes per minute, offering a balance between speed and control for optimal cutting results.

Furthermore, the inclusion of a built-in speed control knob enhances user control during operation, ensuring that the tool adapts seamlessly to the specific demands of the task at hand. This level of precision is particularly beneficial when working with delicate materials or when intricate cuts are required.

3. Blade Compatibility

Versatility is a key aspect of the CP7900, and this is reflected in its compatibility with various types of blades. The tool supports both standard and specialty blades, allowing users to choose the most suitable blade for their specific application. Whether it’s cutting through metal, plastic, fiberglass, or composite materials, the CP7900 proves to be a reliable companion, adapting effortlessly to diverse cutting challenges.

4. Ergonomics and Design

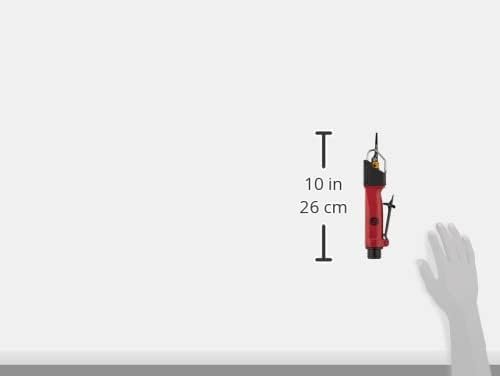

Chicago Pneumatic has prioritized user comfort and convenience in the design of the CP7900. The tool features a compact and lightweight design, weighing in at just over a pound. This makes it easy to handle and maneuver, reducing operator fatigue during prolonged use.

The ergonomic design extends to the handle, which is crafted for a comfortable grip, ensuring that users maintain control and precision throughout their cutting tasks. The inclusion of a safety throttle lever adds an extra layer of protection, preventing accidental starts and ensuring user safety.

5. Durability and Construction

Durability is a hallmark of Chicago Pneumatic tools, and the CP7900 is no exception. The tool is constructed with high-quality materials that withstand the rigors of professional use. The sturdy housing and components contribute to the tool’s longevity, making it a reliable investment for professionals seeking a tool that can withstand demanding work environments.

6. Air Inlet and Hose Size

The CP7900 reciprocating air saw features a standard 1/4-inch NPT (National Pipe Thread) air inlet, ensuring compatibility with a wide range of air hoses and connectors. This standardized inlet size facilitates easy integration into existing pneumatic systems, providing users with flexibility and convenience.

The recommended air hose size for optimal performance is in the range of 3/8 inches to 1/2 inch. This ensures an adequate airflow to the tool, preventing any loss of power and maintaining consistent cutting efficiency. Additionally, the choice of hose size can impact maneuverability, and the CP7900 is designed to work seamlessly with common hose sizes found in workshops and industrial settings.

7. Noise Level and Vibration

In consideration of user comfort, the CP7900 has been engineered to minimize noise and vibration during operation. The tool operates at a noise level below 85 decibels, meeting industry standards for acceptable noise levels in professional settings. This feature is particularly important for users who may be working in confined spaces or alongside colleagues, where noise reduction is a priority.

Vibration levels are also kept to a minimum, ensuring that users experience less hand fatigue and improved control during prolonged use. The reduction in vibration contributes to a smoother cutting experience, enhancing the overall usability of the tool.

8. Blade Changing Mechanism

Changing blades on the CP7900 is a straightforward process, thanks to its user-friendly design. The tool is equipped with a quick-change blade mechanism that allows users to replace blades efficiently, minimizing downtime between tasks. This feature is especially valuable in time-sensitive applications where swift blade changes are essential for maintaining workflow efficiency.

The blade changing mechanism is designed to securely hold the blade in place during operation, preventing any slippage or dislodgment. This ensures that the tool maintains consistent cutting accuracy and safety throughout its use.

9. Additional Accessories

Chicago Pneumatic offers a range of accessories and replacement parts to complement the CP7900 reciprocating air saw. This includes a variety of blades with different tooth configurations and materials to suit specific cutting applications. Users can also find replacement parts such as blade guards, springs, and air filters to extend the life of the tool and ensure it operates at peak performance.

These accessories contribute to the overall versatility of the CP7900, allowing users to customize the tool according to the demands of their work. Having a selection of blades and accessories on hand ensures that operators are well-equipped to handle a diverse range of cutting challenges.

10. Maintenance and Lubrication

Proper maintenance is crucial for the longevity and performance of any pneumatic tool, and the CP7900 is designed with user-friendly maintenance in mind. Regular lubrication of the tool is recommended to ensure smooth operation and prevent premature wear of internal components.

Chicago Pneumatic provides guidelines for the type of lubricant to use and the recommended intervals for lubrication. Following these maintenance practices not only extends the life of the tool but also contributes to consistent performance and reliability.

Advantages of the Chicago Pneumatic CP7900

1. Precision Cutting

The CP7900 excels in delivering precision cuts, thanks to its variable speed control and adjustable stroke length. Users can fine-tune the tool to match the requirements of different materials, ensuring clean and accurate cuts every time. This makes it an ideal choice for tasks that demand a high level of precision, such as metal fabrication, bodywork in automotive repair, and intricate woodworking.

2. Versatility Across Materials

Whether you’re working with metal, plastic, fiberglass, or other composite materials, the CP7900 rises to the occasion. Its compatibility with a range of blades enhances its versatility, allowing users to tackle a variety of cutting applications without the need for multiple tools. This versatility is a significant advantage for professionals who deal with diverse materials in their day-to-day work.

3. Efficient Performance

The combination of a powerful pneumatic motor and adjustable speed control results in efficient cutting performance. The CP7900 effortlessly powers through materials, reducing cutting time and increasing overall productivity. This efficiency is particularly valuable in industrial settings where time is of the essence, helping professionals meet deadlines without compromising on the quality of their work.

4. User-Friendly Design

The user-friendly design of the CP7900 is evident in its compact and lightweight construction. Operators can maneuver the tool with ease, reaching tight spaces and angles without straining their wrists or hands. The comfortable grip and safety features enhance user control and contribute to a positive and safe working experience.

5. Durable Build for Longevity

Chicago Pneumatic’s commitment to durability is evident in the construction of the CP7900. The tool is built to withstand the demands of regular use in industrial and professional settings. This durability not only ensures a longer lifespan for the tool but also minimizes downtime and maintenance costs, making it a cost-effective choice for professionals and businesses.

Conclusion

The Chicago Pneumatic CP7900 Reciprocating Air Saw stands as a testament to the brand’s commitment to delivering top-notch pneumatic tools. With its powerful motor, adjustable speed control, and versatile blade compatibility, the CP7900 addresses the diverse needs of professionals across industries. From precision cutting to efficient performance, this reciprocating air saw offers a myriad of advantages that make it a valuable asset in the toolkit of craftsmen, mechanics, and industrial workers alike. Invest in the CP7900, and experience the cutting-edge precision and power that Chicago Pneumatic is renowned for in the world of pneumatic tools.

Reviews

There are no reviews yet.